PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

KRÜSS Gas Analyzers Kruess Gas Analysers MAT1000 series Kruss Gas Analyzers MAT1100/MAT1200/MAT1400/MAT1500 for O2 and/or CO2

Analyzers >> KRÜSS Gas Analyzers Kruess Gas Analysers MAT1000 series Kruss Gas Analyzers MAT1100/MAT1200/MAT1400/MAT1500 for O2 and/or CO2 measurements NEW

KRÜSS Gas Analyzers Kruess Gas Analysers MAT1000 series Kruss Gas Analyzers MAT1100/MAT1200/MAT1400/MAT1500 for O2 and/or CO2 measurements NEW

Controlling Modified Atmosphere Packaging

"In order to be successful on the market, manufacturers of sensitive or perishable products must be able to guarantee first-class quality over a long period of time. This applies, in particular, to the food industry but also the electronics, pharmaceutical or cosmetics industry.

Modified Atmosphere Packaging (MAP) plays a decisive role in this. Typical protective gases are nitrogen (N2), carbon dioxide (CO2) and oxygen (O2) as well as a mixture of these gases. These are natural components of the ambient air but in modified concentrations that need to be checked. In most food packages, the oxygen concentration is reduced while the carbon dioxide concentration is increased in order to inhibit the growth of aerobic microorganisms. That also allows you to slow down oxidation processes that change the ingredients and thus the taste and colour of the products. Other foodstuff, however, requires a certain oxygen content inside the packaging so it can stay fresh or keep its colour.

But protective gases are not only used in the food industry. Electronic components are also packaged under nitrogen in order to prevent oxidation and corrosion processes. The same applies to pharmaceutical or cosmetic products, for example, in vials or blister packages. In addition, the modified atmosphere stabilises the packaging providing the product with a mechanical protection.

The gas analysers of the MAT1000 series:

Quality assurance and ever increasing consumer requirements make it necessary to control modified atmosphere packaging on a regular basis. Gas analysers must deliver fast, reliable measurement results and be easily integrated into the work process – just like our devices from the MAT1000 series. They are used by many companies for the quality inspection in the lab but also at the production line if sensitive or perishable products are filled or packaged. Our Modified Atmosphere Testers (MAT) are suitable for both the random sampling and the permanent monitoring of the gas mixture used on packaging machines. Their solid metal housing with an interchangeable protective cover offers protection against impact and dirt from the outside.

Analysis of headspace volume:

In order to check the mixture ratio of the protective gases inside a package, a self-adhesive septum is applied to a sampling point. The suction needle of the gas analyser is then inserted through the septum into the headspace of the package. A simple touch on the touch-screen of the device will ensure that the required sample is automatically drawn in. Within a very short time, the oxygen and carbon dioxide content is measured, the nitrogen content calculated, and the results are shown on the display." (KRUSS)

| EASY OPERATION AND HIGH SAFETY STANDARD |

|---|

As a user of our gas analysers, you enjoy many benefits:

|

Individual solutions for any modified atmosphere

In order to meet the different requirements on the quality control of protective gas packaging, we offer four types of gas analysers that are fitted with different sensors and measuring cells.

![]()

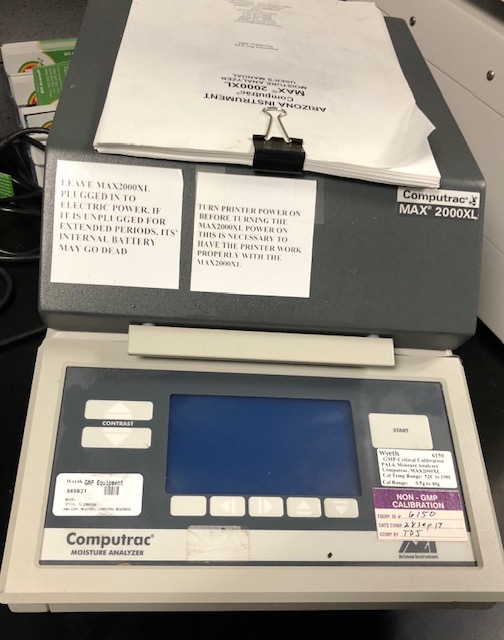

THE REASONABLY PRICED ENTRY-LEVEL MODEL FOR SAMPLE CHECKS

The MAT1100 is the right choice whenever you only need to be concerned with the oxygen concentration or whenever only nitrogen is used. Its electrochemical oxygen cell (EC) measures within the range of 0.5 and 35 volume per cent and with an accuracy of ±0.2 volume per cent. Unlike our other models, the MAT1100 requires very little time to heat up and can therefore be quickly used for occasional measurement or in case of frequent „changes of location“.

![]()

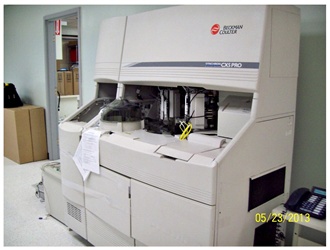

THE ECONOMICAL SOLUTION FOR O2 AND CO2 MEASUREMENTS

If you need to measure the concentrations of oxygen and carbon dioxide, then the MAT1200 will be the appropriate model. In addition to an electrochemical oxygen cell, it features a non-dispersive infrared sensor (NDIR) for the CO2 measurement over the measuring range of 0 and 50 volume per cent and with a high accuracy of ±0.5 volume per cent. The MAT1200 hence covers most carbon dioxide applications in modified atmosphere packaging – at a very attractive price.

![]()

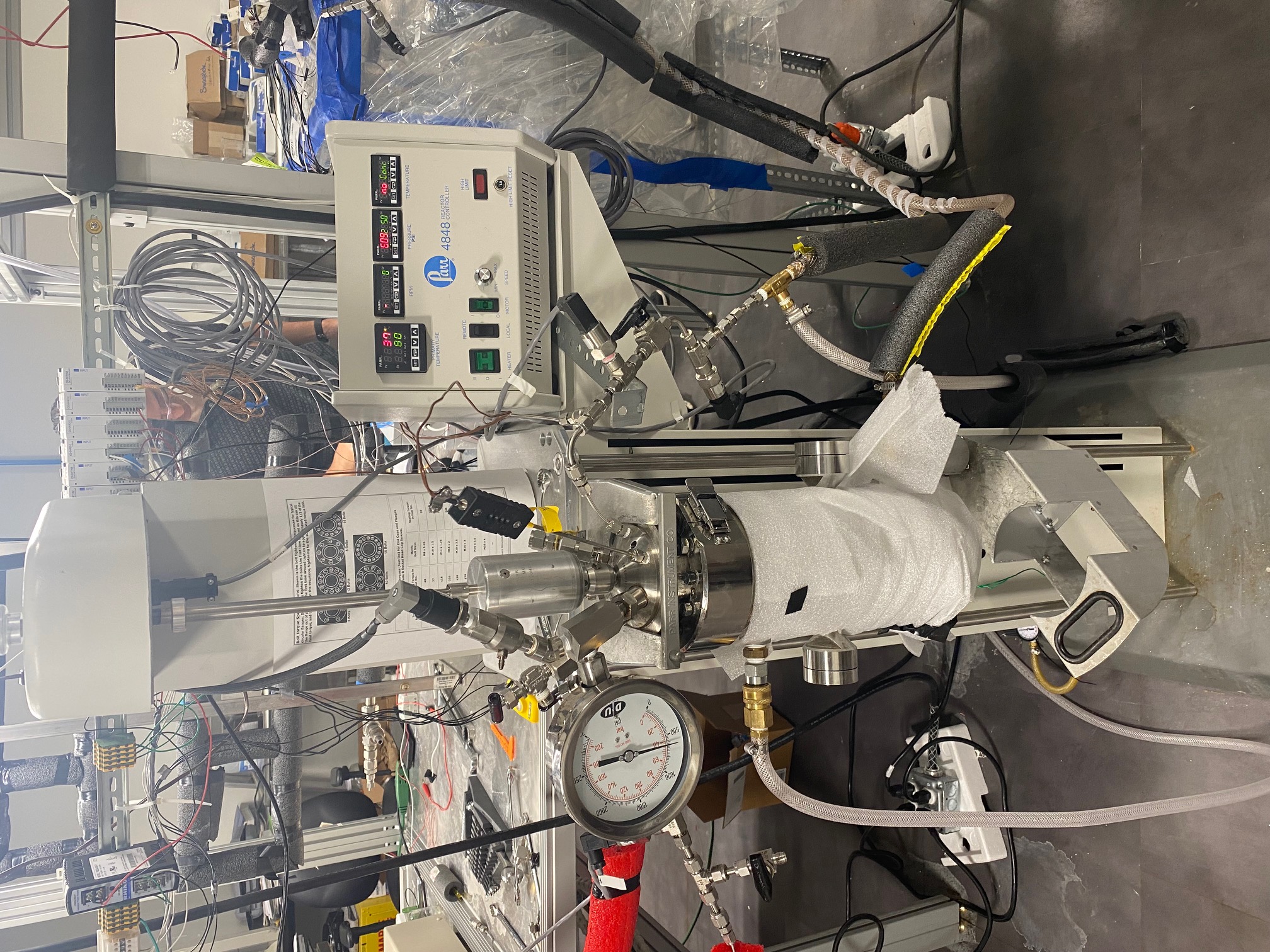

THE SPECIALIST FOR FAST, HIGH-PRECISION OXYGEN MEASUREMENTS

The zirconium dioxide sensor (ZrO2) of the MAT1400 measures the oxygen concentration over the entire measurement range between 0 and 100 volume per cent. Especially in case of a very low concentration, it will achieve an excellent accuracy of ±0.001 volume per cent. The MAT1400 is therefore suitable for the inspection of oxygen-free as well as oxygen-rich modified atmospheres. It can also be used in the cold storage room from ambient temperatures of 10 °C.

![]()

THE ALL-ROUNDER FOR HIGHEST STANDARDS

Fitted with a zirconium dioxide sensor and a nondispersive infrared sensor, the MAT1500 combines the advantages of the MAT1200 and MAT1400 and is our number one when it comes to the range of application, performance and precision. The measurements are completed within only approx. ten seconds. As is the case with the MAT1400, highly precise results can be achieved with single measurements of oxygen concentrations thanks to the min/max detection even if only a small sample volume is available.

Overview of our Gas Analysers

| MAT1100 | MAT1200 | MAT1400 | MAT1500 | |

|---|---|---|---|---|

| AREA OF APPLICATION | Sporadic O2 sample check |

Combined O2 and CO2measurement |

High sample throughput High O2 concentration |

High sample throughput High O2 concentration Combined O2 and CO2 measurement |

| ADVANTAGES | Cost-effective option Fast operational readiness |

Cost-effective option |

Long service life Fast measurement High precision with the lowest O2 concentrations Wide measurement range |

Long service life Fast measurement High precision with the lowest O2 concentrations Wide measurement range |

| Low drift | Low drift Environmentally compensated CO2 measurement |

Drift-free | ZrO2: drift-free NDIR: low drift Environmentally compensated CO2 measurement |

|

| O2 SENSOR | EC | EC | ZrO2 | ZrO2 |

| CO2 SENSOR | NDIR | NDIR | ||

| N2 | Arithmetic determination |

Arithmetic determination |

Easy, intuitive operation for maximum efficiency

The gas analysers of the MAT1000 series feature a self-explanatory, well-arranged user interface. A state-of-the-art TFT display ensures a clear, bright visual representation of all the information. The integrated touch-screen allows even non-expert personnel to intuitively and thus quickly operate the device.

Create your own methods

Freely assignable shortcut keys for the most important functions

Optional secondary and tertiary scale to display up to three measured values

Easy, menu-guided adjustment

Measurements can be triggered with an optional foot switch

A selection of six languages (de, en, fr, es, it, pt)

Intelligent user administration

Integrated measured data storage: complete recording of all measured data as well as system or method settings

Documentation of all measured values of the last 999 measurements

Customise your result reports

For additional details regarding this equipment, please visit http://www.kruess.com/laboratory/products/gas-analysers/ to download the product brochure and data sheet.