PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

Retsch Flotation Tester FT 100 XL NEW PRODUCT

Dissolution >> Retsch Flotation Tester FT 100 XL NEW PRODUCT

Retsch Flotation Tester FT 100 XL NEW

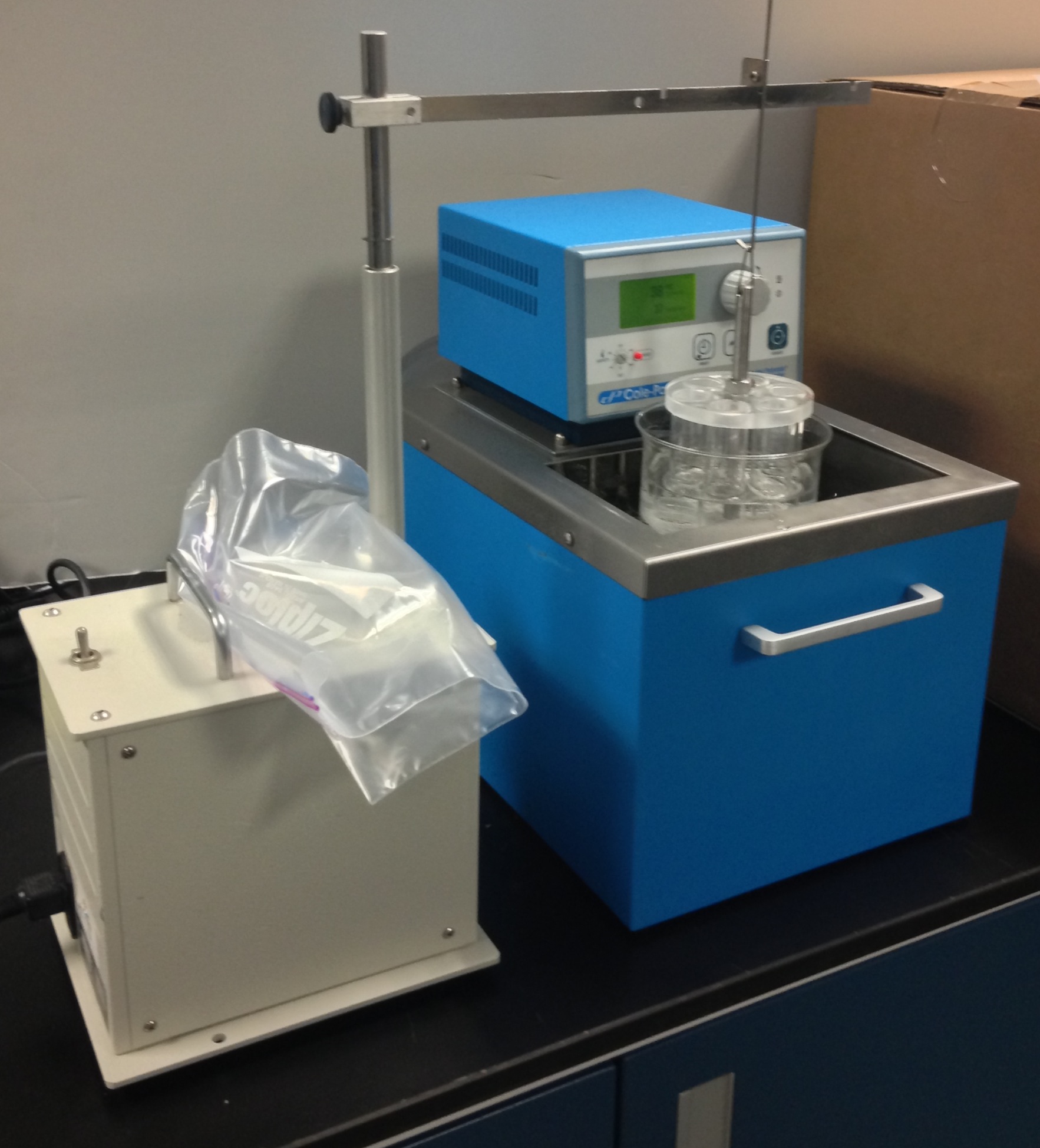

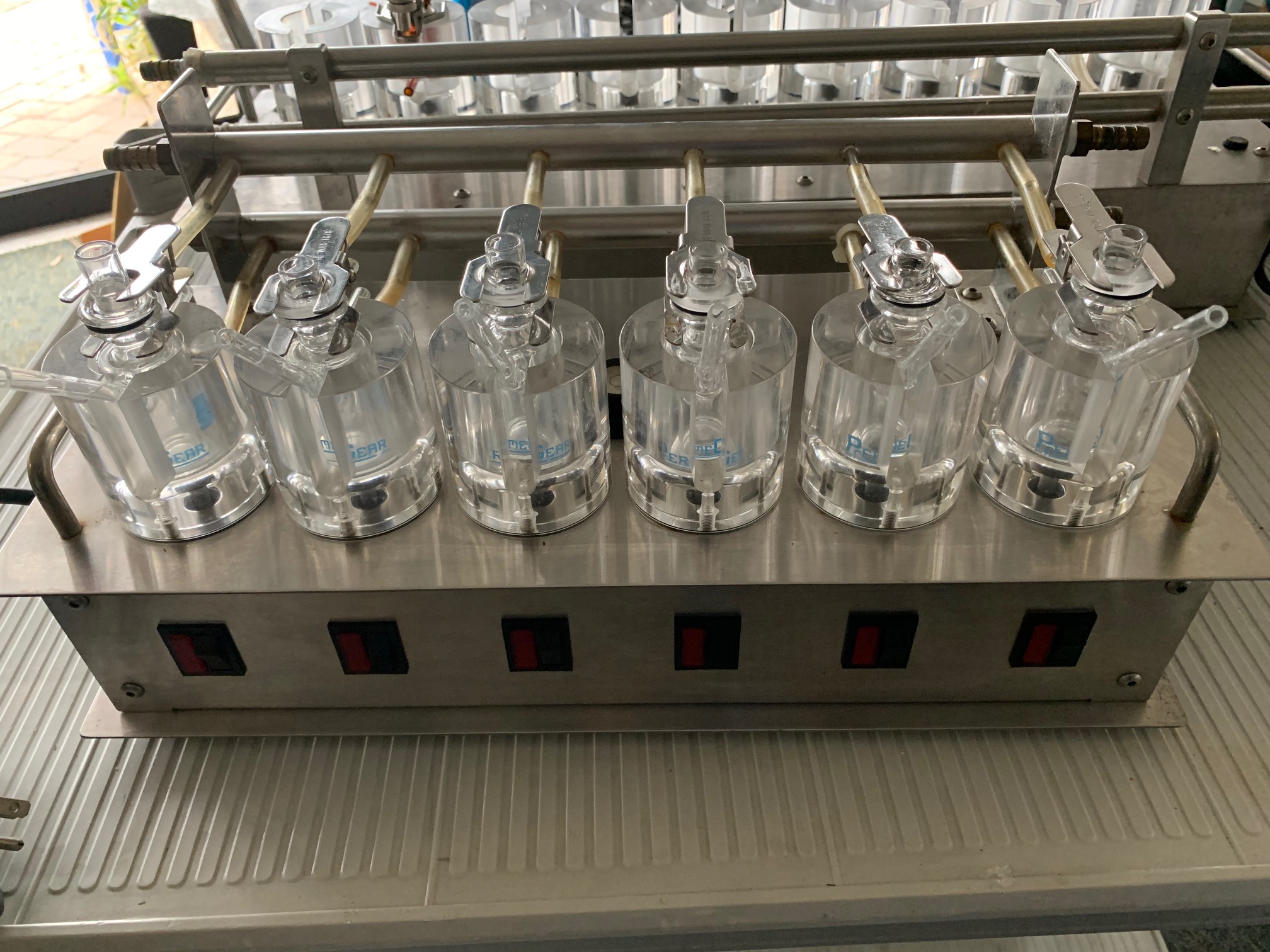

"Flotation is used in gold, copper, lead, zinc, and coal mining to recover fine mineral particles from ore slurry. This technique involves filling the slurry into a frothing solution to separate the particles. Due to their surface tension some particles float to the top with the air bubbles where they can be extracted; fragments which still contain large amounts of ore sink to the bottom of the tank as so-called “tailings”.

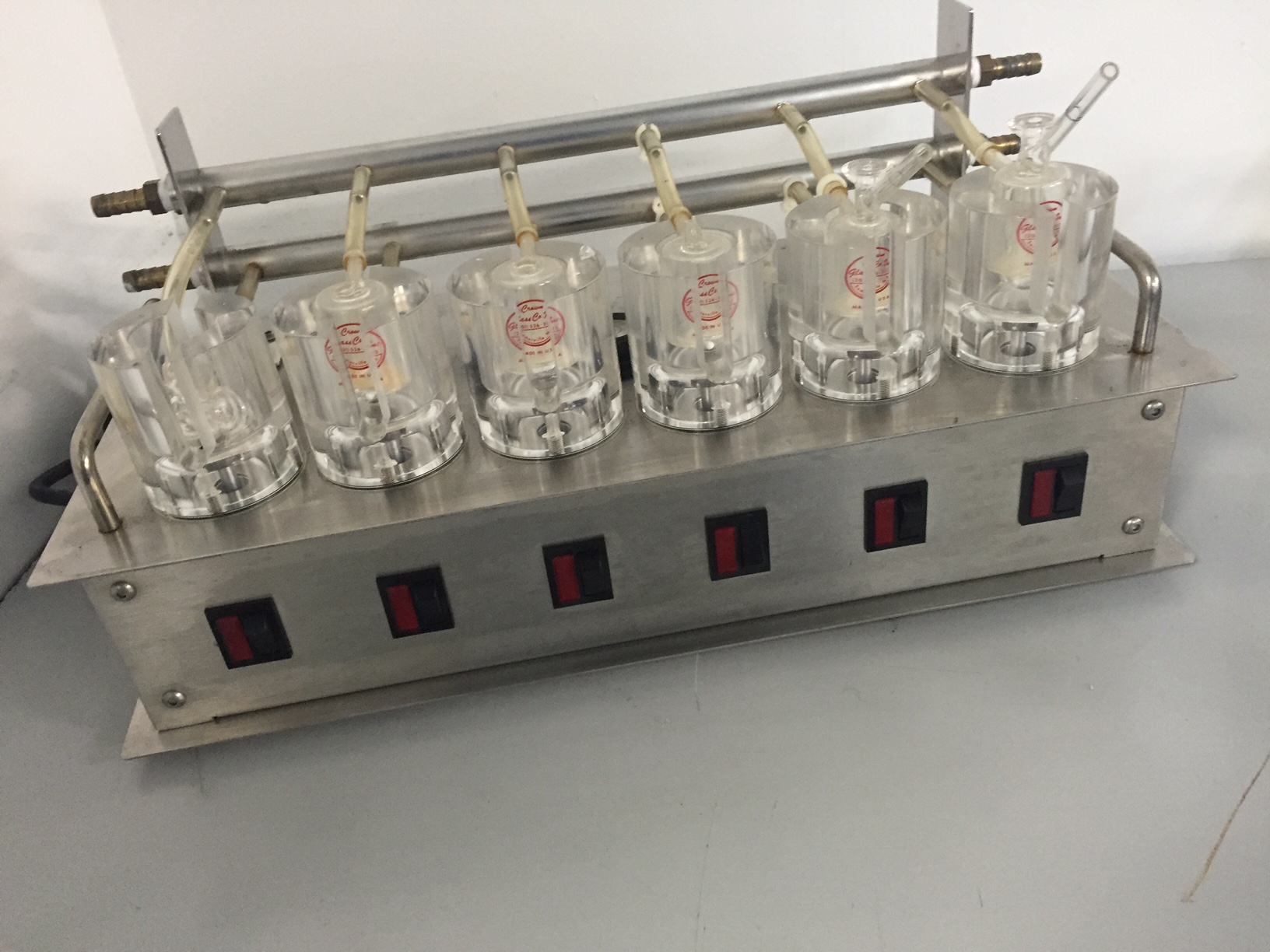

The laboratory flotation machine FT 100 XL is used to determine the percentages of the reagents required in a production flotation cell and for metallurgical sampling. A variety of flotation cells is available for use with the FT 100 XL. Tank and agitator are made of stainless steel. The machine is designed for a material fineness of 500 to 750 microns.

The FT 100 XL is a precise and reliable tool to obtain reproducible test results to ascertain the operational capability of flotation plants." (RETSCH)

Application Examples:

cement, minerals, ores, raw materials, slag, ...

Product Advantages:

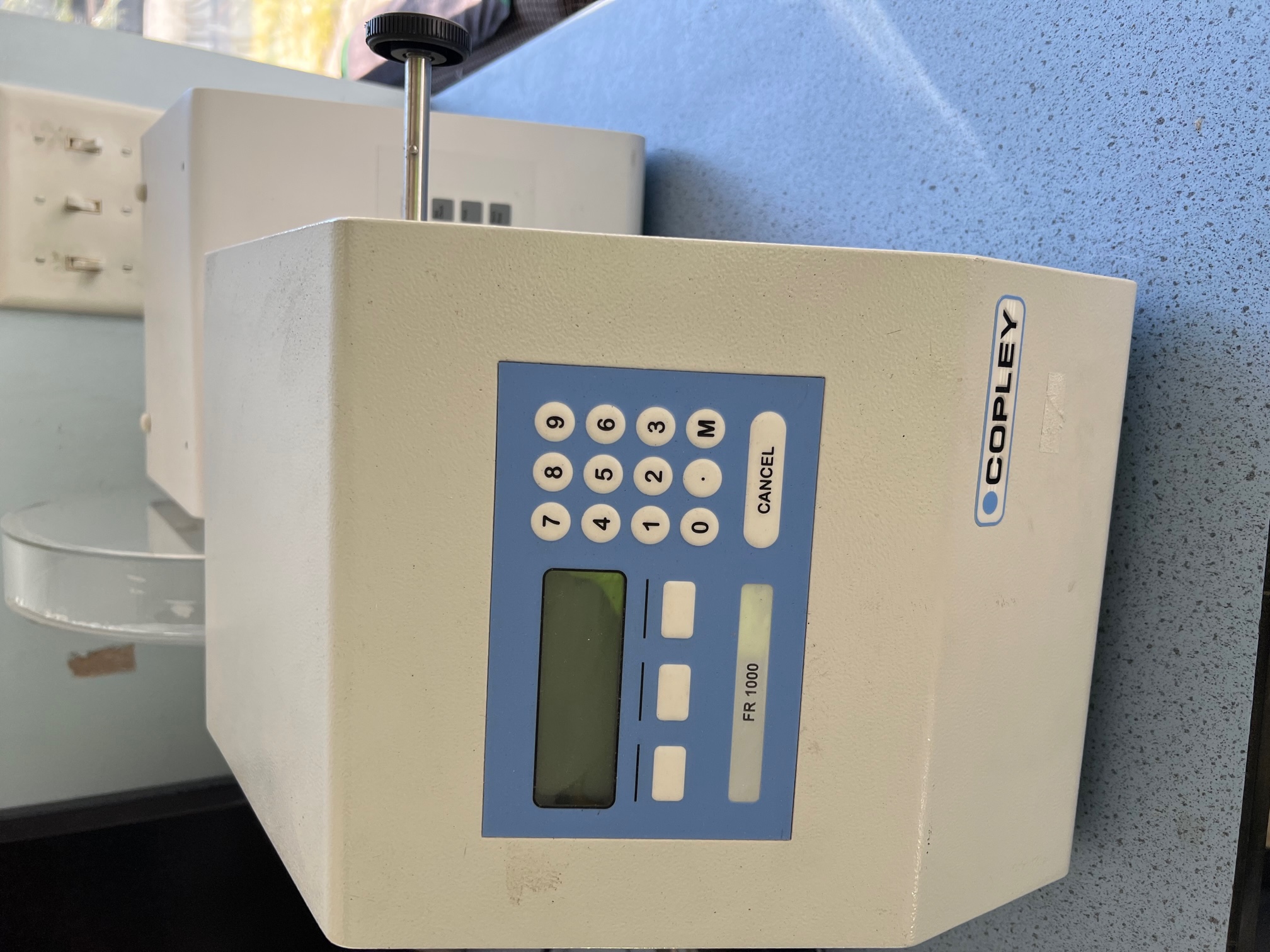

adjustable rotation speed up to 1,200 min-1

range of flotation cells up to 5,000 ml

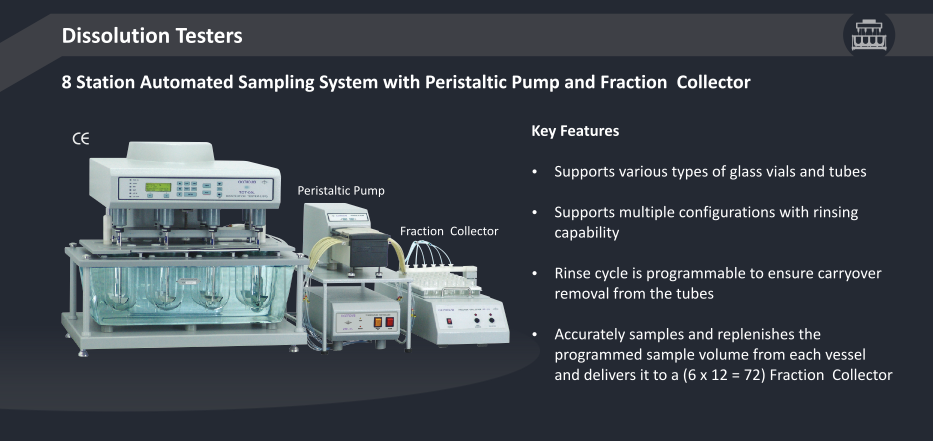

adjustable air flow regulation

convenient parameter setting via display

Features

| Applications | separation of different materials, particularly minerals, by agitating a pulverized mixture of solids in liquids |

| Field of application | construction materials, environment / recycling, geology / metallurgy |

| Feed material | slurries |

| Material feed size* | < 800 µm |

| Batch size / feed quantity* | 5,000 ml, depending on the flotation cell |

| Time setting | adjustable 0 - 99 min |

| Speed setting | adjustable 200 - 1,200 min-1 |

| Electrical supply data | 230 V, 50 Hz |

| Power connection | 1-phase |

| Net weight | ~ 85kg |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"The flotation process involves mixing the finely ground sample materials by rotation with water and various chemicals. Air is then pumped through the slurry mixture and the mineral particles attach themselves to the bubbles and rise to the surface where a concentrated mineral froth is formed. The mineral froth is then extracted and the concentrated mineral is further refined. Waste rock particles drop to the flotation tank’s bottom as tailings." (RETSCH)

For additional details regarding this equipment, please visit http://www.retsch.com/products/assisting/testing/ft-100-xl/ to download the product brochure and data sheet.