PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

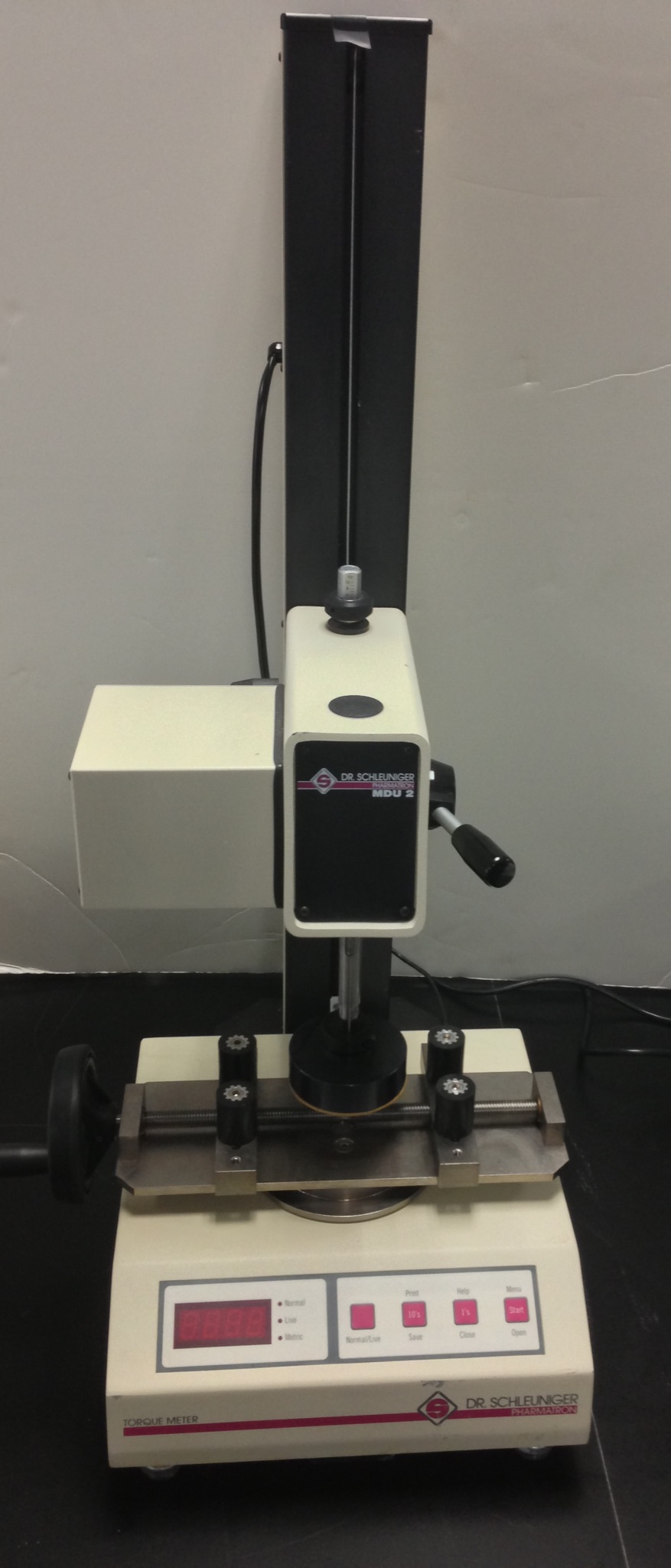

Retsch Impact Tester IT 100 XL (Bond Index) NEW

Dissolution >> Retsch Impact Tester IT 100 XL (Bond Index) NEW

Retsch Impact Tester IT 100 XL (Bond Index) NEW

"A detailed overview and knowledge of the characteristics of a raw material is of utmost importance, especially when planning the layout of a crushing plant. In order to minimize possible risks extensive trials are necessary to obtain information on the properties of the raw materials. A clear definition of the desired throughput capacity and product quality can be made in the planning phase with the help of Bond Index Testing.

The Bond Impact Tester IT 100 XL consists of two hammers mounted on a pendulum and is used for the determination of the Crushing Work Index (CWI). This index describes the competency of ores at larger particle sizes and serves to calculate the energy actually required for the crushing process. At least 10 samples, preferably 20, should be tested. Each broken stone has to pass a 3 inch square mesh and falls on a 2 inch square mesh.

The IT 100 XL Bond Impact Tester is available in a manual or automatic version and complies with the requirements defined by F. C. Bond." (RETSCH)

Product Advantages:

adjustable crushing angle

reproducible crushing results

replaceable hammer tips

convenient parameter setting via display

CE conform version

Features

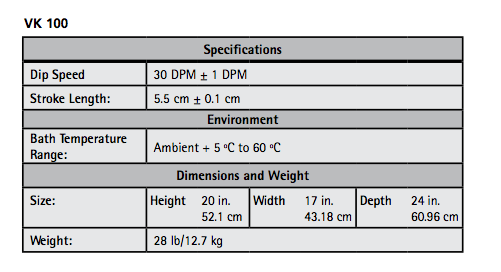

| Applications | quantification of the breaking characteristics of ores and minerals |

| Field of application | construction materials, environment / recycling, geology / metallurgy |

| Material feed size* | < 76 mm / > 50 mm |

| Square mesh | 3" and 2" |

| Crushing angle | adjustable from 10° up to 150° in steps by 5° |

| Batch size / feed quantity* | variable |

| Number of processes | 20 samples |

| Processing time | variable |

| Evaluation | calculation of required energy input |

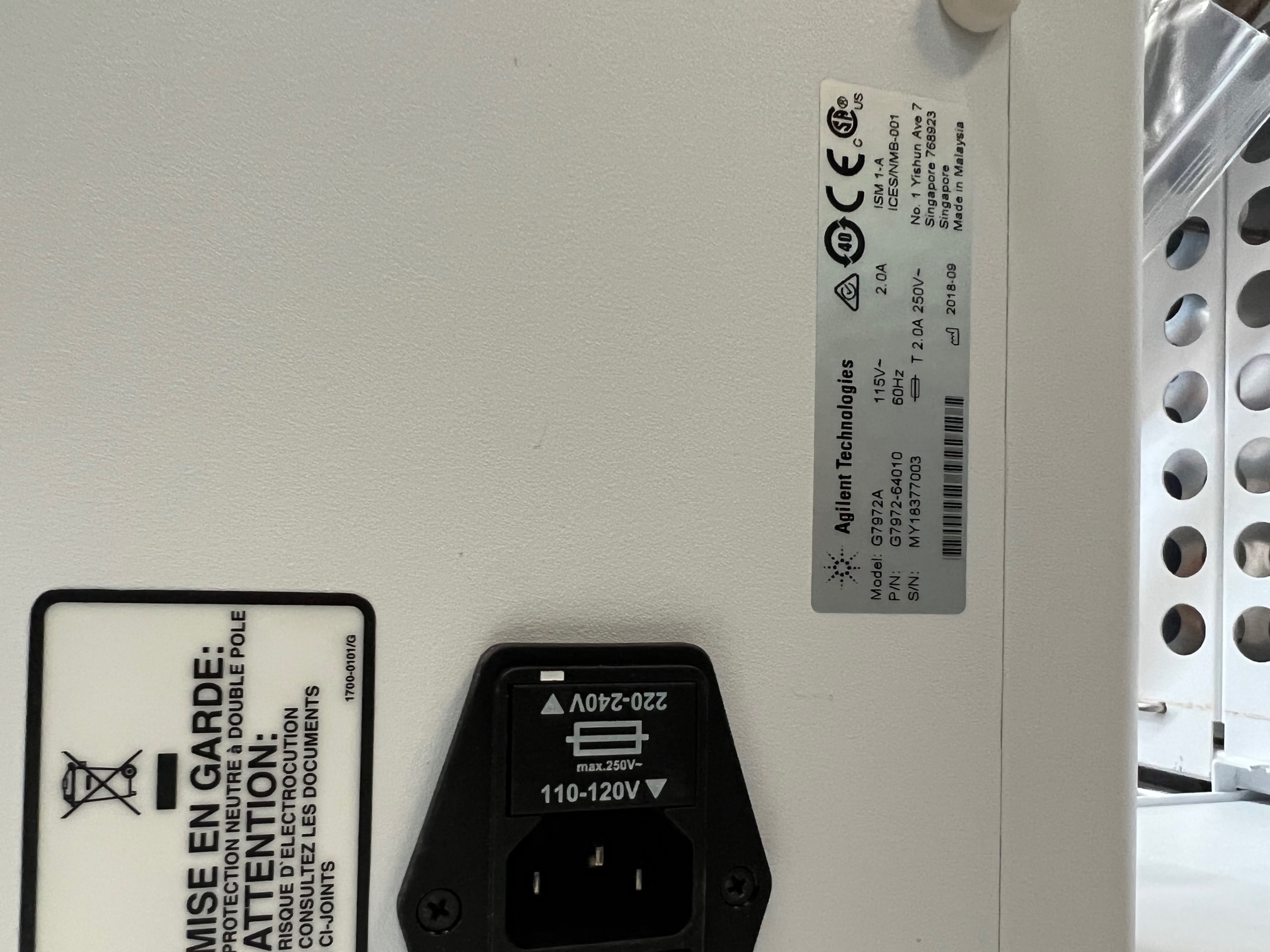

| Electrical supply data | 230 V, 50 Hz |

| Power connection | 1-phase |

| Net weight | ~ 370 kg |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"The hammers are lifted, starting with a 10 degree angle. The rope is then released manually or automatically and the hammers fall down and strike the sample. The sample is checked for cracks and fissures, the number of broken fragments is noted down.

If the sample is still whole, it is again placed on the platform and the process is repeated, increasing the hammer release angle by 5 degrees with each repetition until the sample is broken." (RETSCH)

For additional details regarding this equipment, please visit http://www.retsch.com/products/assisting/testing/it-100-xl/ to download the product brochure and data sheet.